India has a long tradition of manufacturing sugar. References of sugar making by the Indians are found even in the Atharva Veda. India is rightly called the homeland of sugar. Farmers, big or small, face a lot of difficulties when it comes to payment by the sugar mill for their sugarcane crop. This year the wait for money stretched a bit too far.

Dimensions

- Sugarcane Industries: Distribution in India

- Their Importance

- Problems they face

- Government Initiatives

- What else needs to be done?

Content:

Sugarcane Industries: Distribution in India:

- Sugar industry in India is based on sugarcane which is a heavy, low value, weight losing and perishable raw material.

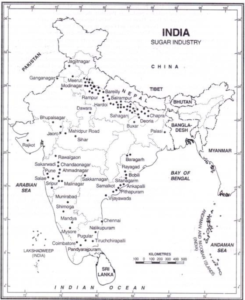

- The sugar industry has two major areas of concentration.

- One comprises Uttar Pradesh, Bihar, Haryana and Punjab in the north and the other that of Maharashtra, Karnataka, Tamil Nadu and Andhra Pradesh in the south.

Sugarcane cannot be stored for long as the loss of sucrose content is inevitable. Also, it cannot be transported over long distances because any increase in transportation cost would raise the cost of production and the sugarcane may dry up on the way.

Their Importance:

- Sugar industry is an important agro-based industry that impacts the rural livelihood of about 50 million sugarcane farmers and around 5 lakh workers directly employed in sugar mills.

- Employment is also generated in various ancillary activities relating to transport, trade servicing of machinery and supply of agriculture inputs.

- India is the second largest producer of sugar in the world after Brazil and is also the largest consumer.

- Today Indian sugar industry’s annual output is worth approximately Rs.80,000 crores

Problems they face:

Sugar industry in India is plagued with several serious and complicated problems which call for immediate attention and rational solutions.

Some of the burning problems are briefly discussed below:

Low Yield of Sugarcane:

- Although India has the largest area under sugarcane cultivation, the yield per hectare is extremely low as compared to some of the major sugarcane producing countries of the world.

- For example, India’s yield is only 64.5 tonnes/hectare as compared to 90 tonnes in Java and 121 tonnes in Hawaii.

- This leads to low overall production and results in short supply of sugarcane to sugar mills.

Short crushing season:

- Manufacturing of sugar is a seasonal phenomena with a short crushing season varying normally from 4 to 7 months in a year.

- The mills and its workers remain idle during the remaining period of the year, thus creating financial problems for the industry as a whole.

Fluctuating Production Trends:

- Sugarcane has to compete with several other food and cash crops like cotton, oil seeds, rice, etc.

- Consequently, the land available to sugarcane cultivation is not the same and the total production of sugarcane fluctuates.

- This affects the supply of sugarcane to the mills and the production of sugar also varies from year to year.

Low rate of recovery:

- The average rate of recovery in India is less than ten per cent which is quite low as compared to other major sugar producing countries.

- For example, the recovery rate is as high as 14-16 per cent in Java, Hawaii and Australia.

High cost of Production:

- High cost of sugarcane, inefficient technology, uneconomic process of production and heavy excise duty result in high cost of manufacturing.

- The production cost of sugar in India is one of the highest in the world.

Small and uneconomic size of mills:

- Most of the sugar mills in India are of small size with a capacity of 1,000 to 1,500 tonnes per day.

- This makes large scale production uneconomic. Many of the mills are economically not viable.

Old and obsolete machinery:

- Most of the machinery used in Indian sugar mills, particularly those of Uttar Pradesh and Bihar is old and obsolete, being 50-60 years old and needs rehabilitation.

- But low profit margin prevents several mill owners from replacing the old machinery by the new one.

Varying Prices:

- Sugar prices have fallen because of the demand-supply mismatch and sugarcane farmers have been incurring heavy losses.

- Fixation of Fair Remunerative Price is a bone of contention between the Centre and sugar mills.

- The Centre decides FRP annually and the states can hike it by issuing a state advisory price. But mills want the price of sugarcane to be linked to the price of sugar.

Unpaid dues to farmers:

- Due to increased sugar production across the country, sugar prices are reduced so much that the sugar mills are finding it difficult to pay dues to farmers.

- Cumulatively they owe Rs 22,000 crore to farmers for cane supplied in 2017-18.

Government Initiatives:

Ethanol Blended Petrol Programme (EBP Programme):

- The Ethanol Blended Petrol Programme (EBP) seeks to achieve blending of Ethanol with motor spirit with a view to reducing pollution, conserve foreign exchange and increase value addition in the sugar industry enabling them to clear cane price arrears of farmers.

- Brazil, the world’s biggest sugarcane producer, depends on ethanol, and not sugar, as the main revenue source from sugarcane and blends 27 per cent ethanol with petrol.

- The Central Government has scaled up blending targets from 5% to 10% under the EBP.

- The procedure of procurement of ethanol under the EBP has been simplified to streamline the entire ethanol supply chain and remunerative ex-depot price of ethanol has been fixed.

Scheme for Extending FInancial Assistance to Sugar Undertakings (SEFASU-2014):

- The Government notified a Scheme for Extending Financial Assistance to Sugar Undertakings (SEFASU-2014) envisaging interest free loans by bank as additional working capital to sugar mills, for clearance of cane price arrears of previous sugar seasons and timely settlement of cane price of current sugar season to sugarcane farmers.

- Interest burden on this loan, for five years is borne by the Government through Sugar Development Fund.

Soft Loan to Sugar Mills:

- A scheme was notified in 2015 to provide soft loans to sugar mills to facilitate clearance of cane price arrears.

- Interest subvention during the moratorium period of one year was borne by the Government. About 32 lakh farmers have been benefited.

Minimum Indicative Export Quotas (MIEQ):

- With a view to improving domestic sugar price sentiments, the Government fixed indicative export targets for each mill proportionate to their sugar production so as to evacuate 4 mMT of sugar stocks.

- No export subsidy or incentive is offered and the industry is expected to export at prevailing international prices and absorb the losses so incurred.

- It is expected that with stock evacuation, domestic sugar prices would increase and reach levels more supportive of cane prices. These are the Minimum Indicative Export Quotas (MIEQ).

- The industry can export greater quantities, and is at liberty to export raw, white or refined sugar depending on global market demand. The Quotas have also been made tradable.

What else needs to be done?

- The pricing shall be done on the basis of scientific and economically viable principles.

- One possible method to increase the crushing season is to sow and harvest sugarcane at proper intervals in different areas adjoining the sugar mill. This will increase the duration of supply of sugarcane to sugar mills.

- The new national policy on biofuels 2018, expands the scope of raw material for ethanol production by allowing use of Sugarcane Juice. Ethanol production should be promoted. Policy modifications to increase the ethanol blending is needed. Better prices for ethanol can also help in export of the same.

- Government should take proactive steps to maintain and revive growth in the sugar industry like the Sustainable Sugarcane Initiative.

- Further, the government should provide subsidies on new technology and equipment to both mill owners and farmers. New attractive schemes shall be launched for increasing investments and empowering entrepreneurs in the sugar industry.

- Intense research is required to increase the sugarcane production in the agricultural field and to introduce new technology of production efficiency in the sugar mills. Production cost can also be reduced through proper utilisation of by- products of the industry.

- For example, bagasse can be used for manufacturing paper pulp, insulating board, plastic, carbon cortex etc. Molasses comprise another important by-product which can be gainfully used for the manufacture of power alcohol.

- This, in its turn, is useful in manufacturing DDT, acetate rayon, polythene, synthetic rubber, plastics, toilet preparations, etc. It can also be utilised for conversion into edible molasses and cattle feed. Press-mud can be used for extracting wax.

Mould your thought: What are the problems faced by Sugar industry in India? Discuss government initiatives to alleviate these problems and suggest steps for improving the situation.

Approach to the answer:

- Introduction

- Discuss problems of sugar industry

- Discuss the government initiatives

- Suggest some solutions to address the problems

- Conclusion