Manifest Pedagogy:

India is the second largest producer of sugar in the world. Sugar industry is an important agro-based industry that impacts rural livelihood of about 50 million sugarcane farmers and around 5 lakh workers directly employed in sugar mills. But the Indian sugar industry has never stood on its feet. If the government ensures proactive reforms, the sector will become globally competitive and financially independent. Cane arrears will be history. There will be no need for the government to subsidize the industry and offer large bail-outs.

In News:–The government recently imposed a cap of 10 million tonnes on the export of sugar for the sugar season 2022 ( October-September) while requiring exporters to take approvals in the form of export release orders from the Department of Food and Public Distribution from June 2022. The move is to ensure sufficient domestic availability and price stability.

Placing it in Syllabus– Agriculture and Agro based Industries.

Static Dimensions

- About Sugarcane Crop

- Sugarcane growing regions

Current Dimensions

- North vs South Divide in Sugar Cane Industry

- Dynamics of Sugar Industry

- Issues faced by Sugarcane Industry

- Various Government Initiatives

- Best Practice- Brazil

- Way Forward

About Sugarcane Crop

- Sugarcane is grown as a Kharif Crop.

- It needs a hot and humid climate with an average temperature of 21°C to 27°C.

- It requires rainfall in the range of 75-150 cm.

- Sugarcane can grow in any soil which can retain moisture. Ideal soil for sugarcane is rich loamy soil.

Sugar Cane growing Areas

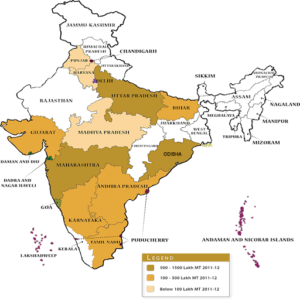

Three distinct belts of sugarcane cultivation can be identified.

- The Sutlej-Ganga plain from Punjab to Bihar contains 51 per cent of the total area and 60 percent of the country’s total production.

- The black soil belt from Maharashtra to Tamil Nadu along the eastern slopes of the Western Ghats.

- Coastal Andhra and the Krishna Valley.

Maharashtra overtook Uttar Pradesh (UP) recently as India’s top sugar producer in 2022.

North-South Divide in India’s sugar industry-

- North

- Extreme weather conditions in summer and winter affect the crop negatively and yield per unit area is low.

- Sugarcane has low sucrose content.

- Crushing season is smaller.

- The cooperative sugar mills are not managed properly.

- They lack modern machinery.

- South

- The climate in the south is suitable for the crop and hence the yield per unit area is high.

- Sugarcane has high sucrose content.

- Crushing season is longer.

- The cooperative sugar mills are better managed.

- They have modern machinery.

Dynamics of sugar Industry: How it functions

- Farmers grow sugarcane and sell it to the sugar mills.

- Sugar mills have to buy the sugarcane from farmers at a fixed rate called Fair and Remunerative Price (FRP) which is decided by the government.

- Since the price of sugar cane does not reflect the market price of sugar there is a price mismatch and the mill owners are not able to pay the farmers when the market price of sugar is low, and thus arrears get accumulated.

- The government provides incentives to these mill owners so that they could clear the arrears.

Issues faced by Sugar Industry

- Problem of Sugarcane Crop

- Low yield per hectare: The average rate of sugar recovery from the sugar cane is less than other sugar producing areas like Java, Hawaii and Australia. For example, India’s yield is only 64.5 tonnes/hectare as compared to 90 tonnes in Java and 121 tonnes in Hawaii.

- Monoculture of sugarcane: Lack of crop rotation in some areas, leads to depletion of nutrients in soil and adversely affects cane productivity.

- Water availability: Irregularity in availability of water for irrigation especially in north India, adversely affecting the sucrose content in the crop.

- Perishable nature of crop: Post harvest deterioration in cane quality on account of staling and delayed crushing contributes to low sugar recovery.

- Problems of Sugar Industry

- Uncertain Production Output-Sugarcane has to compete with several other food and cash crops like cotton, oil seeds, rice, etc. This affects the supply of sugarcane to the mills and the production of sugar also varies from year to year causing fluctuations in prices leading to losses in times of excess production due to low prices.

- Short crushing season-Sugar production is a seasonal industry with a short crushing season varying normally from 4 to 7 months in a year. It causes financial loss and seasonal employment for workers and lack of full utilization of sugar mills.

- Low Sugar recovery rate– The average rate of recovery of sugar from sugarcane in India is less than ten per cent which is quite low as compared to other major sugar producing countries.

- High Production cost– High cost of sugarcane, inefficient technology, uneconomic process of production and heavy excise duty result in high cost of manufacturing. Most of the sugar mills in India are of small size with a capacity of 1,000 to 1,500 tonnes per day thus fail to take advantage of economies of scale.

- Government policy and control- Government has been controlling sugar prices through various policy interventions like export duty, imposition of stock limit on sugar mills, change in meteorology rule etc., to balance supply demand mismatch. But these controls have resulted in unremunerative sugar prices, increasing arrears for sugar mills and dues to be paid to sugarcane farmers.

Problems faced by the Co-operative Sector and Sugar mills

- Sugarcane has a short crushing season varying normally from 4 to 7 months in a year. The mills and its workers remain idle during the remaining period of the year, thus creating financial problems for the industry as a whole.

- Cooperative sugar industry has been eroded by corruption. The structure of the sector lacks transparency and financial accountability.

- There is a nexus between mill owners and politicians and many of the mills are owned by politicians whose main agenda is maximizing profit.

- Lack of professional management.

- Unskilled and untrained workforce.

- Absence of modern management tools and techniques.

Problem of Byproducts

- The main by-products of the sugar industry are bagasse and molasses. The industry faces problems in disposing of these by-products, especially under pollution control mechanism.

Problem of cane farmers

- Inadequate availability of quality seed of new sugarcane varieties to farmers.

- Delays in payment to the cane farmers lead to lack of financial resources for the next season.

- They have to borrow money from money lenders etc and are engulfed in debt trap which leads to suicide in extreme cases.

Government Initiatives

- Fair and remunerative price (FRP): The FRP is the minimum price that sugar mills have to pay to sugarcane farmers for procurement of sugarcane. It is determined on the basis of recommendations of the Commission for Agricultural Costs and Prices (CACP) and after consultation with State Governments and other stakeholders.

- State Advised Price: Although the Central government decides the FRP the state governments can also set a State Advised price which a sugar mill has to pay to the farmers.

- Rangarajan committee (2012) was set up to give recommendations on regulation of the sugar industry. Its major recommendations:

- Abolition of the quantitative controls on export and import of sugar, these should be replaced by appropriate tariffs.

- Committee recommended no more outright bans on sugar exports.

- The central government has prescribed a minimum radial distance of 15 km between any two sugar mills, this criterion often causes virtual monopoly over a large area that can give the mills power over farmers. The Committee recommended that the distance norm be reviewed.

- There should be no restrictions on sale of by-products and prices should be market determined.

- States should also undertake policy reform to allow mills to harness power generated from bagasse.

- Remove the regulations on release of non-levy sugar as it will improve the financial health of the sugar mills, which will lead to timely payments to farmers and a reduction in cane arrears.

Based on the report, the Commission for Agricultural Costs and Prices (CACP) recommended a hybrid approach of fixing sugarcane prices, which involved fair and remunerative price (FRP). The de-regulation of the sugar sector was undertaken to improve the financial health of sugar mills, enhance cash flows, reduce inventory costs and also result in timely payments of cane price to sugarcane farmers.

The recommendations of the Committee relating to Minimum Distance Criteria and adoption of the Cane Price Formula have been left to State Governments for adoption and implementation, as considered appropriate by them. The government has also provided incentives on producing ethanol from B-heavy molasses and cane juice to divert the sugar surpluses towards biofuel, thus indirectly supporting sugar prices. The new Biofuel Policy 2018 has fixed a target of achieving 20 per cent ethanol blending with petrol by 2030.

What could be done?

- Instead of further complicating the matters through dual pricing, digging up the 2012 Rangarajan committee report on sugar would be far better.

- The practical pricing system mooted by the committee should be implemented.

- The proposed benefit sharing formula envisages assigning 70% of the revenue earned by sugar mills from the sale of sugar and its by-products to the cane growers.

- The objective is to link the prices of sugarcane with those of sugar and its by-products.

- This would, in turn, allow the output of both sugarcane and sugar to be determined by market dynamics and stave off scarcities and glutes.

- It would also safeguard the interests of all stakeholders – cane farmers, sugar industry, traders and consumers.

Best Practice- Brazil

- Majority of the sugar mills in Brazil are capable of producing both sugar and ethanol.

- The sugar processing facilities in Brazil are considered as biorefinery, which along with sugar can produce bioethanol and electricity from bagasse.

- These plants are flexible to either produce more sugar or more ethanol depending on the price premium of one over another.

- This model can be replicated in India as well.

Way Forward

The sector requires capital infusion as well as policy and structural improvements. E.g. Modernization of aging mills, particularly in Uttar Pradesh and Bihar, to increase production efficiency. When domestic output is anticipated to exceed domestic consumption, policy modifications should be made to boost exports.

Allowing mills to create more alcohol is a good idea (a higher value product with massive industrial demand). It will improve mills’ financial status, allowing them to pay farmers a price based on market sugar prices. Ethanol production should be encouraged by the government that will reduce the country’s oil import cost and aid in the conversion of sucrose to ethanol, as well as balancing out the country’s excess sugar production.

Government should also popularize innovative methods like Sustainable Sugarcane Initiative (SSI) which uses less seeds, less water and optimum utilization of fertilizers and land for sugarcane production.

Mould your Thought

- Despite being the second largest producer of sugarcane, the Indian sugar industry has never stood on its feet. Critically analyze. Discuss the measures to be taken to solve the crisis in the Sugarcane Industry.

Approach to the answer-

- Brief about Sugarcane Industry

- Challenges faced by the industry

- Strengths and opportunities of India’s Sugarcane Industry

- Steps that needs to be taken

- Conclusion