In news: The Aqua Rejuvenation Pilot Plant (ARP) installed at CSIR-CMERI recently can help to reach towards a Zero Liquid Discharge Ecology

The Aqua Rejuvenation Pilot Plant (ARP) of CSIR

- To remove the water contaminants & to purify the sewage water ,CSIR-CMERI developed innovative technology in combination with chemical & physical processes such as

- Mechanical segregation & filtration

- Coagulation-flocculation techniques and

- Chemical/physical adsorption.

- It comprehensively treats WasteWater, based upon diverse purification parameters.

- The approx. 24,000 litres of Water that can be rejuvenated using ARP, will be sufficient for almost 4 acres of Agricultural Land (barring seasonal variations in water requirements).

- It is capable of removing all pollutants from sewage (below W.H.O recommended level) and based upon geographical variations they may be modified.

- The filter media is also locally source-able so as to ensure that there would not be any stress in the supply chain for scaled-up manufacturing of ARP.

How does it purify sewage water?

The methods of purification applied by CSIR-CMERI in this technology are

- Sedimentation (settlement of flocculated or coagulated particles)

- Filtration (process of removing solids from Liquid) and

- Aeration (Oxidation and Hydration).

Key benefits

- The technology will help in solving two problems at one go:

- In one hand it converts sewage water to potable water which may be used for agricultural purposes thereby conserving the fresh water resources

- On the other hand it helps to reduce the burden of pollutant enriched grey water converting it into potable one.

- An integrated mechanical and physico-chemical treatment processes based water purification system for effective removal of sewage water contaminants.

- The technology is economical in terms of maintenance and affordable in terms of operation.

- Sustainability towards healthy livelihood generation

- Selective backwash without dismantling any part of the plant; less cumbersome approach.

Significance of the technology

- ARP has maximum capacity to treat 40,000 litres/day in its scaled-up version. With this technology, CSIR-CMERI will incrementally reach towards a Zero Liquid Discharge Ecology.

- The treated water processed from the ARP is preferable for agricultural purposes and with enhanced settling time it can be used for drinking purposes.

- This treated water will help to improve the environment by fixation of carbon dioxide and will also provide food security.

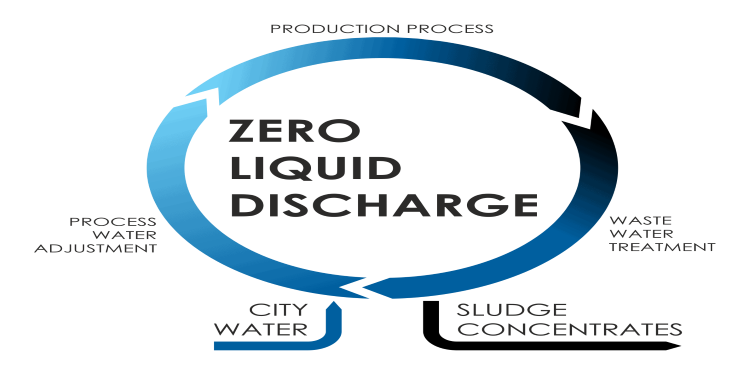

What is a Zero Liquid DischargeZLD)?

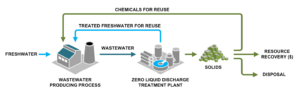

- It refers to a treatment process in which the plant discharges no liquid effluent into surface waters, in effect completely eliminating the environmental pollution associated with treatment.

- It is a combination of technologies that work together to minimize wastewater as much as technically and economically practical, often resulting in a concentrated solid product and high-quality clean water for re-use or environmental discharge.

- It is achieved by treating wastewater through recycling and then recovery and reuse for industrial purposes.

Components of ZLD

A systematic ZLD is made up of the following components:

- pretreatment (physicochemical and Biological)

- RO (membrane processes)

- evaporator and crystallizer (thermal processes)

How does it work?

ZLD systems employ advanced wastewater/desalination treatment technologies to purify and recycle virtually all of the wastewater produced

Benefits of ZLD

Following are the benefits of ZLD system

- Wastewater discharge is avoided by recycling.

- Recovery of water and salt aids in reducing the cost of operation of ZLD.

- It promotes the sustainability of the industry and the environment at large.

- There is less use of water by the textile industry, which means water is available for other purposes such as irrigation (agriculture) and domestic utilities.

- ZLD helps recover the environment.

- The sludge can be effectively used by the cement industry.