In news– Reliance Industries Ltd of India has recently released a short video on social media platform Instagram highlighting the cutting-edge algae-to-fuel technology it has developed.

Key updates-

- The company has been successfully running large algae raceway ponds the last five years at their facility near Jamnagar, to convert sunshine, CO2 and seawater into bio-oil.

- It also displayed the utilisation of catalytic hydrothermal liquefaction technology to convert algae biomass to oil.

- Under this process, water is used as solvent under high temperature and pressure to extract oil from the biomass.

- The benefits of this technology include direct utilisation of wet biomass without any need for drying and conversion of every organic fragment of biomass into oil and without any wastage.

- At the global level, oil and gas giant ExxonMobil partnered with Viridos (formerly Synthetic Genomics) to commercialise algal biofuels.

Algae biofuels-

- Algae can synthesise large volumes of oil (20 times more than that of mustard per acre), grow fast (10 times quicker than terrestrial plants) and capture carbon dioxide (CO2).

- Microalgae are excellent at converting CO2 and sunlight into oil-rich biomass, especially when compared to land-based crop plants like oil palm and soy.

- By adapting microalgae to function as cell factories producing energy-dense oils that can easily be refined into renewable diesel and jet fuel, we can reduce greenhouse gas emissions by 70 per cent.

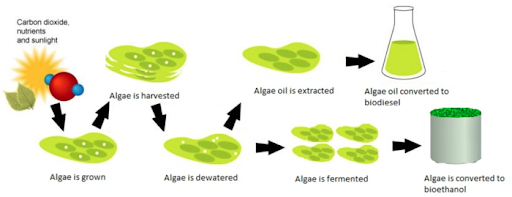

- Algae are sometimes grown to make algae biofuels, which make up the third generation of biofuels. Many types of algae can be used and processed to become a biofuel.

- Biofuel is a fuel made from living things, or the waste of a living thing, also known as biomass.

- The algae oils can be converted to biodiesel and the remaining material can be used to create bioethanol.

The challenges-

The major challenges associated with algae biofuel include-

- Large water requirements.

- High cost of growth nutrients.

- Expensive biomass harvesting, and

- Difficult oil extraction from algae cells.

- Producing a kilogram of biodiesel requires 3.73 tonnes of water, 0.33 kg of nitrogen and 0.71 kg of phosphate.

- Additionally, the energy cost of extracting oil from algae biomass is 10 times higher than the energy cost of extracting soybean oil.